Autoswage®

Based on our patented ball and taper technology, First Subsea has developed a range of high pressure pipe and tube fittings to complement the growing range of mechanical handling tools and connectors that are used throughout the world. Autoswage® is a simple, fast and more efficient way of connecting pipe without tools, with a high pressure capability, with is unique point - push - connect method of installation.

It comprises of load carrying mandrels within the Autoswage® connector, featuring ball and taper gripping technology. The connectors are a female/female type or female/welded type and they are designed to fit over the outside of the existing pipes/fittings of any size.

The compact Autoswage® connector provides:

- Simple, fast and effective way of connecting pipe

- Quick connect for a variety of liquids and gases applications and pressures

- Simple point - push - connect all without tools

- Stab on connection - no risk of applying too much or too little torque

Available in a range of different materials including:

- Carbon steel

- Stainless steel

- Duplex

- Super duplex

- Inconel

Seals

Typical subsea applications include:

|

|

Pipe Repair |

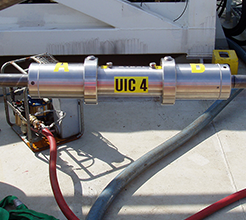

Umbilical Intervention Connector |

|

Information |

Autoswage to bypass leaking valve and pipe on subsea manifold with limited access at approximate depth 400m | Umbilical Intervention Connectors (UIC) needed in response to leakage from two pipe members |

|

Autoswage® Tool |

Autoswage Inconel tools with Silicon Nitride balls | Double ended Autoswage design to suit 1” jumper tube |

|

Sealing |

Z70B (HNBR) seals with PEEK backup rings | PTFE and Nitrile Seals |

| Operating Pressure | 3,750 PSI (258 Bar) | 10,000 PSI (690 Bar) |

|

Test pressure |

4,688 PSI (323 Bar) | 15,000 PSI (1,034 Bar) |